Knife Steel Basics

Selection of Knife Steels

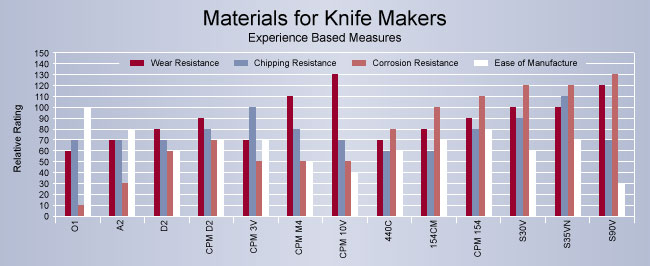

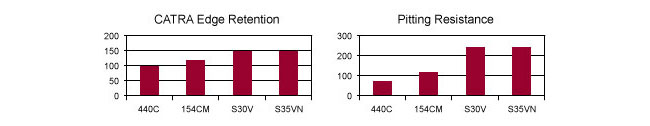

The utility of a knife depends on optimizing all the factors affecting its performance. Usually, conditions of use (applied loads, abrasive environments, impacts, and other factors) determine how well the knife holds up. Most knife failures are related to such mechanical causes. However, with a variety of steels available for manufacturing knives, it is often possible to choose a knife steel with a favorable combination of properties for particular uses. By comparing the levels of metallurgical properties offered by different steels, knifemakers can determine which steels are best suited for fixing or resisting performance problems, or for enhancing knife performance. Knife steels can be categorized and compared by those properties which have a direct influence on performance: hardness, toughness (impact resistance), wear resistance, and corrosion resistance.

| Knife Steels | |

| General Purpose 01, A2, D2 Improved Toughness 3V |

Improved Wear Resistance M4, 10V, S30V, S90V Corrosion Resistance 440C, 154CM, CPM154, 90V, S35VN, S90V |

Historically, custom knife steels have included 01, A2 and D2, with occasional use of corrosion and wear resistant grades such as 440C and 154 CM. 01, A2 and D2 are familiar to most custom knife makers and users. They combine good all-around performance properties with low cost, wide availability, and relatively easy fabrication. However, they sometimes do not provide the level of performance needed for challenging applications. Specifically, where abusive use and infrequent resharpening are desired, other higher alloy steels might be used. Traditionally, other properties, such as impact resistance, may be sacrificed in order to gain the higher wear properties. Conversely, steels chosen for their resistance to impact or breakage may not be capable of high wear resistance. An understanding of these knife steel properties and related issues permits selection of the optimum steel for most applications.

Knife users can examine heavily used blades to determine which property may have been lacking, or which properties should be improved, and what other properties must be considered in alternate materials with the required improved properties.

Properties of Knife Steel

Hardness is a measure of a steel's resistance to deformation. Hardness in knife steels is most commonly measured using the Rockwell C test. Hardened knife steels are generally about 58/62 HRC (hardness Rockwell C), depending on the grade. Most are typically about 58/60 HRC, although some are occasionally used up to about 62 HRC.

Knife edges which plastically deform in service possess insufficient hardness. Permanent bending of the blade or permanent deflection of the cutting edge indicates insufficient hardness. Because a steel's resistance to permanent deflection is directly related to the hardness, not the grade, corrective actions for deformation may include increasing hardness, or decreasing operating loads by increasing blade thickness. Changing grades will not help a deformation problem, unless the new grade is capable of higher hardness.

Toughness, as considered for high hardness knife steels, is the relative resistance of a material to breakage, chipping, or cracking under impact or stress. Toughness may be thought of as the opposite of brittleness. Toughness testing is not as standardized as hardness testing. It may be difficult to correlate the results of different test methods. Common toughness tests include various impact tests and bend fracture tests.

In service, wear failures are usually preferable to toughness failures (breakage). Breakage failures can be unpredictable, catastrophic, and even a safety concern. Conversely, wear failures are usually gradual, and can be anticipated and planned for. Toughness failures may be the result of inadequate material toughness, or a number of other factors, including heat treatment, fabrication (grinding abuse), or a multitude of usage issues. Toughness data is useful to predict which steels may be more or less prone to chipping or breakage than other steels, but toughness data cannot alone predict the performance life of a knife.

Wear resistance is the ability of material to resist being abraded or eroded by contact with work material, or outside influences (dirt, grit, bone, etc.) Wear resistance is provided by both the hardness level and the chemistry of the knife blade. Wear tests are quite specific to the circumstances creating the wear and the application of the knife. Most wear tests involve creating a moving contact between the surface of a sample and some destructive medium. There are 2 basic types of wear damage in knives, abrasive and adhesive. Wear involving erosion or rounding of edges is called abrasive wear. Abrasive wear does not require high pressures. Abrasive wear testing may involve sand, sandpaper, or various slurries or powders. Wear from intimate contact between two relatively smooth surfaces, such as steel on steel, carbide on steel, etc., is called adhesive wear. Adhesive wear may involve actual tearing of the material at points of high pressure contact due to friction.

Corrosion Resistance is a measure of a knife steel's resistance to attack in high humidity, damp, or salt environments. This resistance is established by the addition of chromium to the composition. Developing corrosion resistance in a heat treatable, wear resistant steel is a challenge that has been met with numerous specialty CPM alloys. Relative resistance is often measured in salt spray and water spray environments.

Heat Treatment of Tool Steels

Knife Steels are usually supplied in the annealed condition to facilitate manufacture. These steels must be heat treated to develop their characteristic properties. The heat treating process alters the alloy distribution and transforms the soft matrix into a hard matrix capable of withstanding the pressure, abrasion and impacts inherent in knife use. Each step of the heat treating cycle is designed to perform a specific function, and, like links in a chain, the final product is only as good as its weakest component.

Preheating, or slow heating, of knife steels during heat treatment is necessary to avoid thermal shock and distortion. Preheating is done to just below a critical transformation temperature. The part is then held long enough to allow the full cross-section to reach a uniform temperature. Once the entire part is equalized, further heating to the austenitizing temperature will allow the material to transform more uniformly.

Austenitizing at an elevated temperature is necessary to harden knife steels. The actual temperature used depends on the chemical composition of the steel. The temperature may be varied somewhat to tailor the resulting properties to specific applications. Higher temperatures permit slightly higher hardness or compressive strength. Lower temperatures permit higher material toughness at a slightly lower temperature.

Quenching the steel from the austenitizing temperature causes the steel to fully harden to martensite, which will provide the material's strength. How fast a steel must be cooled to fully harden depends on the chemical composition. For highly alloyed tool steels which harden from over 2000°F, the quench rate from about 1800°F to below 1200°F is critical for optimum heat treat response and material toughness. No matter how knife steels are quenched, the resulting structure, martensite, is extremely brittle, and under great stress. If put into service in this condition, most knife steels would shatter. Some steels will spontaneously crack in this condition even if left untouched at room temperature. For this reason, as soon as knife steels have been quenched by any method to hand-warm (about 125/150°F), they should be immediately tempered.

Tempering is performed to stress-relieve the brittle martensite which was formed during the quench. Most steels have a fairly wide range of acceptable tempering temperatures. In general, use the highest tempering temperature which will provide the necessary hardness for the knife. The rate of heating to, and cooling from the tempering temperature is not critical. Sudden drastic temperature swings should be avoided. The material should be allowed to cool completely to room temperature (50/75°F) or below between and after tempers. Most steels must be held at temperature for a minimum of two to four hours for each temper. A rule of thumb is to allow one hour per inch of thickest section for tempering, but in no case less than two hours regardless of size.

Size Change is unavoidable in heat treated tool steels because of the resultant changes in their microstructure. Most tool steels grow between about 0.0005 and 0.002 inch per inch of original length during heat treatment.

| Chemistries / Heat Treatment Guidelines | ||||||||||

| Alloy | C | Cr | W | Mo | V | Hardening Temp. F/C | Tempering Temperatures Rc after 2x 2Hr tempers |

|||

| O1 | 0.9 | 0.5 | 0.5 | --- | 0.25 | 1500F/815C | 300F/150C 64Rc |

400F/205C 62Rc |

500F/260C 59Rc |

600F/315C 56Rc |

| A2 | 1.0 | 5.25 | --- | 1 | 0.3 | 1775F/970C | 400F/205C 61Rc |

500F/260C 60Rc |

600F/315C 59Rc |

700F/370C 58Rc |

| D2 | 1.5 | 11.5 | --- | 1 | 1 | 1850F/1010C | 400F/205C 61Rc |

500F/260C 60Rc |

600F/315C 59Rc |

700F/370C 58Rc |

| CPM D2 | 1.5 | 11.5 | --- | 1 | 1 | 1850F/1010C | 400F/205C 61Rc |

500F/260C 60.5Rc |

600F/315C 60Rc |

700F/370C 59Rc |

| 3V | 0.8 | 7.5 | --- | 1.3 | 2.75 | 1875F/1025C 1950F/1065C 2050F/1120C |

1000F/540C-56Rc 1000F/540C-59Rc 1000F/540C-61Rc |

1025F/550C-54Rc 1025F/550C-57Rc 1025F/550C-60Rc |

1050F/565C-51Rc 1050F/565C-54Rc 1050F/565C-57Rc |

|

| M4 HC | 1.4 | 4 | 5.5 | 5.25 | 4 | 1975F/1080C 2050F/1120C 2150F/1175C |

1025F/550C-60Rc 1025F/550C-62Rc 1025F/550C-64Rc |

1050F/565C-59Rc 1050F/565C-61Rc 1050F/565C-63Rc |

1100F/595C-56Rc 1100F/595C-59Rc 1100F/595C-62Rc |

1150F/620C-53Rc 1150F/620C-55Rc 1150F/620C-58Rc |

| 10V | 2.45 | 5.25 | --- | 1.3 | 9.75 | 1950F/1065C 2050F/1120C 2150F/1175C |

1000F/540C-61Rc 1000F/540C-62Rc 1000F/540C-64Rc |

1025F/550C-59Rc 1025F/550C-60Rc 1025F/550C-63Rc |

1050F/565C-57Rc 1050F/565C-58Rc 1050F/565C-61Rc |

1100F/595C-52Rc 1100F/595C-54Rc 1100F/595C-56Rc |

| 440C | 1.0 | 17.5 | --- | 0.5 | --- | 1875F/1025C | 212F/100C 59Rc |

400F/205C 56Rc |

600F/315C 55Rc |

800F/425C 54Rc |

| 154CM | 1.05 | 14 | --- | 4.0 | --- | 1950F/1065C | 212F/100C 61Rc |

400F/205C 59Rc |

600F/315C 56Rc |

800F/425C 57Rc |

| CPM 154 | 1.05 | 14 | --- | 4.0 | --- | 1950F/1065C | 212F/100C 61Rc |

400F/205C 60Rc |

600F/316C 57Rc |

800F/425C 58Rc |

| S30V | 1.45 | 14 | --- | 2.0 | 4.0 | 2000F/1090C | 400F/205C 60Rc |

600F/315C 59Rc |

1000F/540C 58.5 |

|

| S35VN | 1.35 | 14 | 2.0 | 3.0 Cb 0.5 |

2000F/1090C | 400F/205C 60Rc |

600F/315C 59Rc |

1000F/540C 58.5 |

||

| S90V | 2.30 | 14 | --- | 1.0 | 9.0 | 2050F/1120C 2150F/1175C |

500F/260C-58Rc 500F/260C-60Rc |

600F/315C-58 600F/315C-60 |

700F/370C-58Rc 700F/370C-60Rc |

1000F/540C-58Rc 1000F/540C-60Rc |