CPM 10V Powder Metal Tool Steel

CPM 10V powder metal tool steel is a versatile tool and die steel which provides extremely high wear resistance in combination with relatively high impact toughness. A large volume of hard vanadium carbides provides the high wear resistance. The good impact toughness is the result of the fine grain size, small carbides, and superior cleanliness of the powder metallurgy (PM) microstructure. CPM 10V offers substantially better wear resistance than the high-carbon, high-chromium die steels such as D2 and D7.

Composition

| C | Mn | Si | Cr | Mo | V |

| 2.45 | 0.50 | 0.90 | 5.25 | 1.30 | 9.75 |

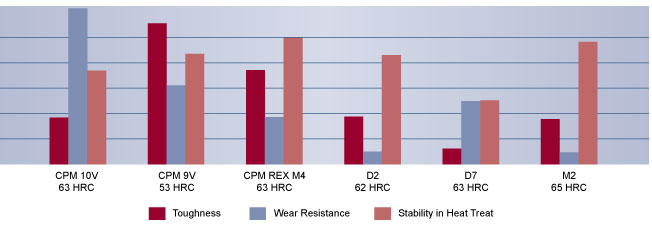

Relative Properties

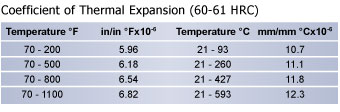

Physical Properties

- Density: 0.268 lb/in3 (7418 kg/m3)

- Specific Gravity: 7.41

- Modulus of Elasticity: 32 x 106 psi (221GPa)

- Machinability: 35-40% of a 1% carbon steel

Heat Treating Instructions

Critical Temperature: Ac1: 1540°F (838°C)

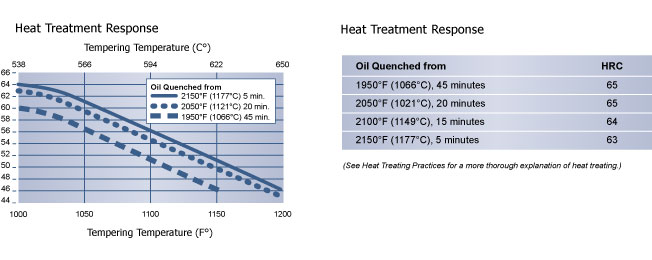

Hardening

Preheating: 1500-1550°F (816-845°C), equalize.

Austenitizing (High Heat): Heat rapidly from the preheat, typically by transferring to a second furnace.

For Optimum Wear Resistance:

Soak for 5 to 15 minutes

Furnace or Salt Bath: 2150 (1177°C)

For Balance of Wear Resistance and Toughness:

Soak for 15 to 30 minutes.

Furnace or Salt Bath: 2050°F (1121°C)

For Maximum Toughness and minimum distortion in cooling:

Soak for 30 to 60 minutes.

Furnace: 1975°F (1080°C)

Salt Bath: 1950°F (1066°C)

Quenching: Air, pressurized gas, warm oil, or salt. Sections less than 3” thick may be air cooled to maximum hardness. Sections 3” thick or more must be quenched at a faster rate, using one of the methods below, to attain maximum hardness. For pressurized gas, the furnace should have a minimum quench pressure of 4 bars. The quench rate to below 1000°F (538°C) is critical to obtain the desired properties.

For oil, quench until black, about 900°F (482°C), then cool in still air to 150-125°F (66-51°C). For salt maintained at 1000-1100°F (538-593°C), equalize in the salt, then cool in still air to 150-125°F (66-51°C).

Tempering: Temper immediately after quenching. Typical temperature range is 1000-1100°F (538- 593°C). Do not temper below 1000°F (538°C). Hold at temperature for 2 hours then air cool to ambient temperature. Double tempering is required. Triple tempering is required when austenitized at 2100°F (1149°C) or higher.

Annealing

Annealing must be performed after hot working and before rehardening.

Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1600 - 1650°F (871 - 899°C), and hold at temperature for 1 hour per inch of maximum thickness: 2 hours minimum. Then cool slowly with the furnace at a rate not exceeding 30°F per hour (17°C per hour) to 1000°F (538°C). Continue cooling to ambient temperature in the furnace or in air. The resultant hardness should be a maximum of 277 HBW.

*CPM, 1V, 3V, 9V, 10V, 15V, S30V, S90V, Rex M4, Rex T15, and Rex 76 are trademarks of Crucible Industries LLC