Data Sheet - 154CM

| Typical Composition | ||

| C | Cr | Mo |

| 1.05 | 14.00 | 4.00 |

154 CM® is a modification of 440C martensitic stainless steel to which has been added. 154 CM® has better better and better hot-hardness than 440C. For it offers better than 440C. It also has higher attainable hardness and better through hardening characteristics than 440C.

The typical applications include cutlery, bearings, valve ports, and bushings.

Surface Treatments

If surface treatments such as CVD, PVD, or nitriding are used, ensure that the coating process temperature is below the tempering temperature. NOTE: Nitriding will reduce the corrosion resistance of Crucible® 154 CM® or any other stainless steel.

Due to its higher carbide volume, Crucible® 154 CM® is a little more difficult to machine than 440C. With high speed or carbide tooling, the following machining parameters are suggested:

| Machining Operation | Speed (fpm) | Feed(in/rev) |

| High Speed Tools | ||

| Turning | 50/60 | 0.003 |

| Forming | 50/60 | 0.001 |

| Drilling | 40 | 0.002 |

| Cutoff | 50/60 | 0.001 |

| Carbide Tools | ||

| Turning | 150 | 0.010 |

| Forming | 100 | 0.0015 |

| Cutoff | 100 | 0.0015 |

| Grade | HRC | Wear Resistance | Total Carbide Volume |

| 154 CM® | 58.5 | 49 mg. | 175% |

| 440C | 57.5 | 66 mg., 55mg. | 12% |

*Wear resistance measured by the pin abrasion method. Lower number (mg.) is a lower weight loss 9 in mg. and therefore better wear resistance.

| Hot Hardness | |||||

| Heat Treatment |

Initial HRC |

HRC tested at 400F 500F 600F |

Final HRC |

||

| A | 62 | 59 | 58 | 55 | 60 |

| B | 62 | 55 | 62 | ||

| C | 64 | 57 | 64 | ||

This data sheet is for informational purposes only. Alloy characteristics are subject to change due to chemical composition and/or processing. We do not certify the material’s suitability for specific applications.

Thermal Treatments

Annealing: Heat to 1650°F (900°C),hold 2 hrs., slow cool no faster than 25°F (15°C) per hour to 1200°F (650°C), then furnace cool or cool in still air to room temperature. Crucible® 154 CM® can be cycle annealed by heating to 1600°F (900°C), hold 2 hrs., cool to 1300°F (704°C), hold 4 hrs., then air cool.

Annealed Hardness: About BHN 235

Stress Relieving

Annealed Parts: Heat to 1100-1300°F (595-705°C), hold 2 hours, then furnace cool or cool in still air.

Hardened Parts: Heat to 25-50°F (15-30°C) below the original tempering temperature, hold 2 hours, then furnace cool or cool in still air.

Hardening

Preheat: Heat to 1400°F (760°C), Equalize.

Austenitize: 1900-2000°F (1037-1093°C), hold time at temperature 30-60 minutes.

Quench: Oil or positive pressure (4 bar minimum) to below 125°F (50°C), or salt quench to about 1000°F (540°C), then air cool to below 125°F

(50°C). Salt bath treatment, if practical, will ensure the maximum attainable toughness for a given hardening treatment.

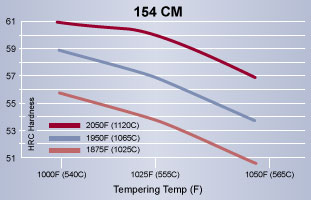

Temper: Twice at 400-1200°F (204-650°C), 2 hours minimum each time.

Note: As with all martensitic stainless steels, tempering at 800-1100°F (425-600°C), will result in sensitization which causes a minor reduction in both corrosion resistance and toughness. We recommend that this tempering range be avoided.

Aim hardness: HRC 55-62

| Heat Treat Response Hardness HRC |

||||||

| Austenitizing Temperature | ||||||

| Tempering Temp. | 1900°F (1038C) |

1950°F (1065C) |

2000°F (1093C) |

|||

| Time at Temp. | 1 hr. | 1 hr. | 1 hr. | |||

| Quench | Oil | Oil & Freeze |

Oil | Oil & Freeze |

Oil | Oil & Freeze |

| As Quenched | 62 | 63 | 61 | 63 | 54 | 63 |

| 400°F(540C) | 59 | 60 | 59 | 62 | 52 | 62 |

| 600°F(540C) | 56 | 59 | 56 | 60 | 50 | 60 |

| 800°F(540C) | 56 | 56 | 57 | 60 | 50 | 61 |

| 900°F(540C) | 56 | 57 | 58 | 61 | 52 | 61 |

| 1000°F(540C) | 54 | 58 | 60 | 61 | 54 | 63 |

| 1050°F(565C) | 51 | 52 | 55 | 56 | 52 | 58 |

| 1100°F(593C) | 47 | 48 | 47 | 48 | 49 | 51 |

| 1200°F(649C) | 43 | 44 | 45 | 46 | 45 | 47 |

| Time at Temp. | 2 hrs. | 2 hrs. | 2 hrs. | |||

| No. of Tempers | 2 | 2 | 2 | |||

| *Results may vary with hardening and section size. Salt or oil quenching will give maximum response. Vacuum or atmosphere cooling may result in up to 1-2 HRC points lower. | ||||||

Recommended Heat Treat Practice

To completely transform any retained austenite, a freezing treatment with dry ice at -100°F (-74°C) is recommended either after the quench or in between the two tempers. The freezing treatment is most effective right out of the quench, however complex parts with sharp corners are more safely frozen between the two tempers. Thin sections can be successfully quenched in forced air and will obtain results to those in the table above.