Graph-Air® (A10) Cold Work Tool Steel

Graph-Air A10 tool steel is an air-hardening, graphitic tool steel with outstanding resistance to metal-to-metal sliding wear and galling. The steel contains a uniform dispersion of graphite particles, which impart excellent machinability and non-seizing characteristics. The graphite particles make the steel self-lubricating in dry environments, and help to retain oil in lubricated environments.

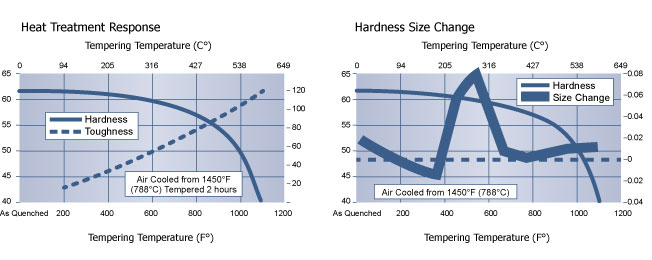

Graph-Air A10 tool steel can be hardened to over 60 Rockwell C from a relatively low hardening temperature, which minimizes size change and distortion during heat treatment.

APPLICATIONS: Thread gauges, master gages, cams, bushings, sleeves, meat granulator plates, arbors, forming rolls,shear blades, punches, dies, bar feed guides and other machine tool parts.

Composition

| C | Mn | Si | Ni | Mo |

| 1.35 | 1.80 | 1.20 | 1.85 | 1.50 |

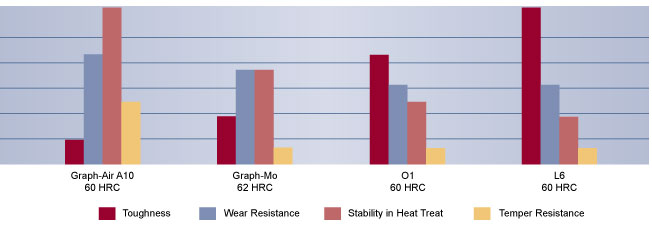

Relative Properties

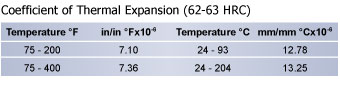

Physical Properties

- Density: 0.277 lb/in3 (7680 kg/m3)

- Specific Gravity: 7.680

- Modulus of Elasticity: 30 x 106psi (207 GPa)

- Machinability: 85-90% of a 1% carbon steel

Heat Treating Instructions

Hardening

Preheating: Preheating is not required, but for tools with complex geometries, may be beneficial for dimensional stability. Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1200-1250°F (649-677°C) and equalize.

Austenitizing (High Heat): Heat slowly from the preheat to 1450-1550°F (788-843°C).

Up to 2 in. (51mm) thickness: use 1450°F (788°C)

2 in. (51mm) to 4 in. (101.6mm) thickness: use 1475°F (802°C).

Over 4 in. (101.6mm) thickness: use 1500°F (816°C)

Quenching: Pressurized gas, warm oil, or salt. For pressurized gas, a rapid quench rate to below 1000°F (538°C) is critical to obtain the desired properties. For oil, quench until black, about 900°F (482°C), then cool in still air to 150 -125°F (66-51°C). For salt maintained at 1000-1100°F (538-593°C), equalize, then cool in still air to 150 -125°F (66-51°C).

Tempering: Temper immediately after quenching. The typical tempering range is 300 - 500°F (149 -260°C). Hold at temperature for 1 hour per inch (25.4 mm) of thickness, 2 hours minimum, then air cool to ambient temperature. The actual hardness obtained is dependent upon the section size of the part being quenched and tempered

To minimize internal stresses in cross sections greater than 3 inches (76.2 mm) and to improve stability in parts that will be EDM'd after heat treatment, a soaking time of 4 to 6 hours at the tempering temperature is strongly recommended.

Cryogenic Treatment: Refrigeration treatments should typically be performed after the temper, and must be followed by a second temper.

Annealing

Annealing must be performed after hot working. Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1450°F (788°C), and hold at temperature for 2 hours. Cool at 20°F (11°C) per hour to 900°F (482°C) then air cool to ambient temperature. Reheat to 1150°F (621°C), hold for 6 hours, then air cool to ambient temperature. The resultant hardness should be a maximum of 269 HBW.

Softening for Reworking

To anneal for reworking after a tool has been hardened, an abbreviated treatment may be used. Heat to 1450°F (788°C), hold for 2 hours. Cool to 1260°F (682°C) at any convenient rate, then cool at 20°F (11°C) per hour from 1260 (682°C) to 1000°F (538°C). Hold at 1000°F (538°C) for 3 hours, then air cool to ambient temperature.