A2 Tool Steel

A2 Tool Steel is a versatile, air-hardening tool steel that is characterized by good toughness and excellent dimensional stability in heat treatment. A2 is intermediate in wear resistance between O1 oil-hardening tool steel and D2 high-carbon, high-chromium tool steel. A2 provides an effective combination of strength and toughness, tool performance, price, and a wide variety of product forms.

APPLICATIONS: Punches and dies, chuck jaws, cutting tools for woodworking, tooling for plastic injection, dowel pins, hammers, industrial knives, and gage

Composition

| C | Mn | Si | Cr | Mo | V |

| 1.00 | 0.75 | 0.30 | 5.0 | 1.00 | 0.25 |

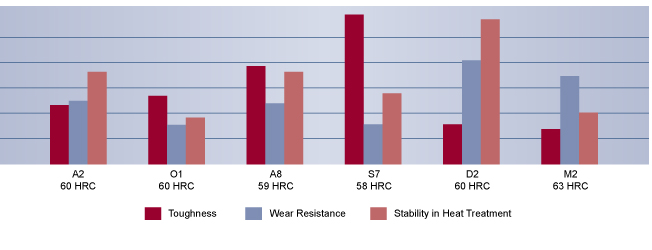

Relative Properties

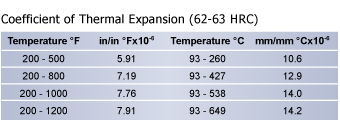

Physical Properties

- Density: 0.284 lb/in3 (7861 kg/m3)

- Specific Gravity: 7.86

- Modulus of Elasticity: 30 x 106 psi (207GPa)

(207 GPa W/m/°K) - Machinability: 70% of a 1% carbon steel

Heat Treating Instructions

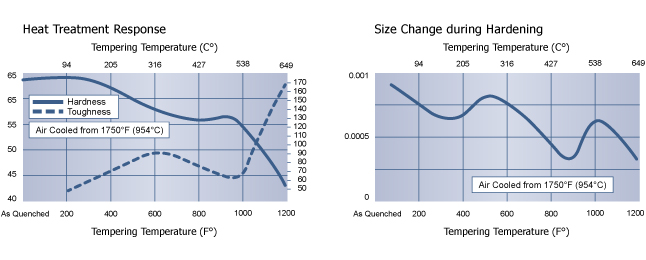

Hardening

Critical Temperature: Ac1: 1460°F (793°C)

Preheating: Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1150-1250°F (621-677°C) and equalize. Then heat to 1300-1400°F (704-760°C).

Austenitizing (High Heat): Heat slowly from the preheat. Furnace or Salt: 1725-1750°F (941-954°C) Soak for 30 minutes for the first inch (25.4 mm) of thickness, plus 15 minutes for each additional inch (25.4 mm).

Quenching: Air, pressurized gas, or interrupted oil to 150-125°F(66-51°C).

Note: Sizes over 3 inches (76.2mm) in cross section may not achieve full hardness by cooling in still air. It is usually necessary to increase the quench cooling rate between 1400 to 900°F (760 to 482°C) by using an air blast, pressurized gas, or an interrupted oil quench. For the oil quench, quench until black, about 900°F (482°C), then cool in still air to 150-125°F(66-51°C).

Tempering: Temper immediately after quenching. Hold at temperature for 1 hour per inch (25.4 mm) of thickness, 2 hours minimum, then air cool to ambient temperature. The typical tempering range is 350 to 500°F (177 to 260°C).

To minimize internal stresses in cross sections greater than 6 inches (152.4 mm) and to improve stability in tools that will be EDM'd after heat treatment, a soaking time of 4 to 6 hours at the tempering temperature is strongly recommended.

Cryogenic Treatment: Some prefer to do cryogenic treatment as an extension of the quench from the austenitizing treatment. Others prefer to cryogenically treat after tempering.

Annealing

Annealing must be performed after hot working and before re-hardening.

Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1550°F (843°C), and hold at temperature for 1 hour per inch (25.4mm) of maximum thickness; 2 hours minimum. Then cool slowly with the furnace at a rate not exceeding 50°F per hour (28°C per hour) to 1000°F (538°C). Continue cooling to ambient temperature in the furnace or in air. The resultant hardness should be a maximum of 235 HBW.