D7 Tool Steel

D7 Tool Steel is a high-carbon, high-chromium air-hardening tool steel that exhibits exceptional wear resistance. The high carbon and vanadium contents result in numerous, hard vanadium carbide particles in the steel. These carbides exhibit a hardness that is equivalent to approximately 80 to 85 Rockwell C. Resists wear from sliding contact with other steels as well as from contact with dry and wet slurries of hard abrasive particles such as sand, shot blast media, and ceramics.

APPLICATIONS: Brick mold liners, briquetting dies, shot blasting equipment liners, tools for ceramic extrusion and molding, powder compaction tooling, deep drawing dies, flattening rolls, and machine tool ways.

Composition

| C | Mn | Si | Cr | Mo | V |

| 2.30 | 0.40 | 0.40 | 12.50 | 1.10 | 4.00 |

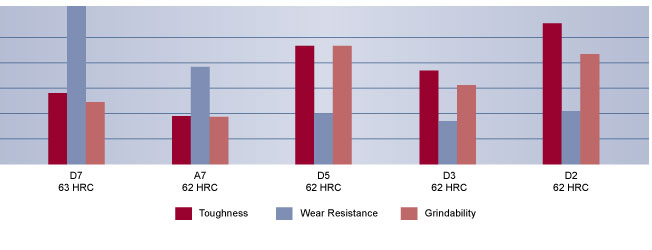

Relative Properties

Physical Properties

- Machinability: 30-35% of a 1% carbon steel

Heat Treating Instructions

Hardening

Preheating: 1400-1500°F (760-816°C)

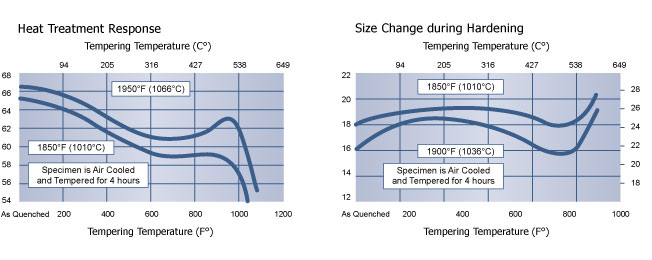

Austenitizing (High Heat): Heat rapidly from the preheat. Furnace or Salt: 1850-2000°F (1010-1093°C) For maximum toughness, use 1850-1900°F (1010-1038°C). For maximum wear resistance use 1950-2000°F (1038-1093°C).

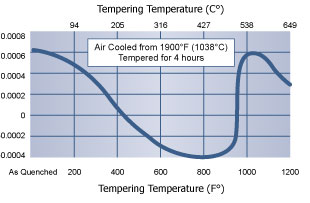

Soak at temperature for 15 minutes per inch (25.4 mm) of thickness; 30 minutes minimum. A minimal dimensional change will occur if an austenitizing temperature of 1900°F (1038°C) is used.

Quenching: Air, warm oil, or pressurized gas. For air cooling, cool in still air to 150-125°F (66-51°C). Sections 10 inches (254 mm) thick or more must be quenched at a faster rate, using one of the methods below, to attain maximum hardness.

For pressurized gas, a minimum quench rate of 300°F per minute (167°C per minute) to below 1000°F (538°C) is critical to obtain the desired properties. For oil, quench until black, about 900°F (482°C), then cool in still air to 150-125°F (66-51°C). For salt maintained at 1000-1100°F (538-593°C), equalize in the salt, then cool in still air to 150-125°F (66-51°C).

Tempering: Temper immediately after quenching. The typical tempering temperature is 300°F (149°C) for maximum wear resistance. Hold at temperature for four hours then air cool to ambient temperature. For maximum toughness, double temper, 2 hours plus 2 hours, at temperatures above 950°F (510°C).

Annealing

Annealing must be performed after hot working and before re-hardening.

Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1600-1650°F (871-899°C), and hold at temperature for 1 hour per inch (25.4mm) of maximum thickness; 2 hours minimum. Then cool slowly with the furnace at a rate not exceeding 50°F per hour (28°C per hour) to 1000°F (538°C). Continue cooling to ambient temperature in the furnace or in air. The resultant hardness should be a maximum of 262 HBW.