420 MQ Plastic Mold Steel

420 MQ Plastic Mold Steel is a highly-refined, mold quality stainless steel that is engineered to exhibit excellent polishability, good corrosion resistance, and good wear resistance. 420 MQ is melted using an electric-arc furnace, is refined by the argon-oxygen-decarburization (AOD) process, and is further enhanced to aerospace quality levels using Vacuum- Arc or Electro-Slag Remelting. These special melting and forging practices result in ultra-high micro-cleanliness and a homogeneous microstructure.

420 MQ is a superior material for the manufacture of plastic molds that require high hardness for good parting line retention and sealing between colored resins. It also resists attack from the corrosive vapors that are produced during molding of some plastic resins. The corrosion resistance also enhances extended tool storage in humid environments. The high cleanliness and homogeneity make 420 MQ a superb choice for mold cavities that require photoetching/texturizing or the highest lens-quality polished finishes.

APPLICATIONS: Plastic mold cavities, plastic extrusion dies, cutlery, surgical and dental instruments, gauges, valves, shafts, cams and ball bearings.

Composition

| C | Mn | Si | Cr | V |

| 0.38 | 0.45 | 0.40 | 13.60 | 0.30 |

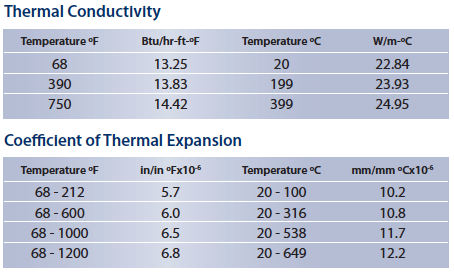

Physical Properties

|

|

Heat Treating Instructions

HARDENING

Critical Temperatures: Ac1: 1475ºF (802ºC) Ac3: 1585ºF (863ºC)

Preheating: To minimize distortion in complex tools use a double preheat. Heat at a rate not exceeding 400º per hour (222º C per hour) to 1150-1250ºF (621- 677ºC), equalize, then raise to 1400-1500ºF (760-816ºC) and equalize. For normal tools, use only the second temperature as a single preheating treatment.

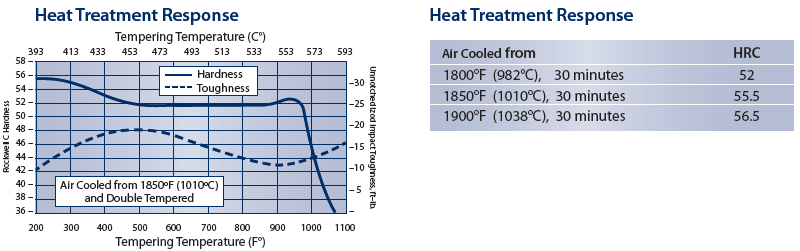

Austenitizing (High Heat): Heat rapidly from the preheat. Furnace or Salt: 1800-1900°F (982-1038°C). For maximum toughness, use 1800ºF (982ºC). For maximum resistance to thermal fatigue, use 1900ºF (1038ºC).

Quenching: Air, pressurized gas, or warm oil. Section thicknesses up to and including 5 inches (127 mm) in thickness. Add an additional 10 minutes of soak time for each additional inch (25.4 mm) of thickness. For pressurized gas, a minimum quench rate of approximately 30ºF per minute (18ºC) per minute to below 1000ºF (538ºC) is required to obtain the optimum properties in the steel. For oil, quench until black, about 900ºF (482ºC), then cool in still air to 150-125ºF (66-51ºC).

Tempering: Temper immediately after quenching. The typical tempering range of 700ºF (371ºC) will result in a hardness of approximately 51 to 53 HRC. However, tempering temperatures in the range of 400 to 775ºF (204-413ºC) may be used. Hold at the tempering temperature for 1 hour per inch (25.4 mm) of thickness, but for no less than 4 hours, then air cool to ambient temperature. Double tempering is required. To maximize toughness, a third temper is recommended.

ANNEALING

Annealing must be performed after hot working and before re-hardening. Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1525-1625°F (830-885°C), and hold at temperature for 1 hour per inch of maximum thickness; 2 hours minimum. Then cool slowly with the furnace at a rate not exceeding 40°F per hour (22°C per hour) to 1000°F (538°C). Continue cooling to ambient temperature in the furnace or in air. The resultant hardness should be a maximum of 235 HBW.