M42 Super High Speed Steel

M42 super high speed steel is a premium cobalt high speed steel with a chemical composition designed for high hardness and superior hot hardness. These properties make the steel an excellent choice for machining high-strength and pre-hardened steels, high-hardness alloys, and the difficult-to-machine, nonferrous super alloys used in the aerospace, oil, and power generation industries.

M42 exhibits excellent wear resistance by virtue of high heat-treated hardness (68 to 70 HRC), and the high cobalt content imparts the hot hardness. As such, the cutting edges on tools made from M42 super high speed steel stay sharp and hard in heavy-duty and high-production cutting applications.

APPLICATIONS: Twist drills, taps, milling cutters, reamers, broaches, saws, knives, and thread rolling dies.

Composition

| C | Si | Cr | W | Mo | V | Co |

| 1.08 | 0.45 | 3.85 | 1.50 | 9.50 | 1.20 | 8.00 |

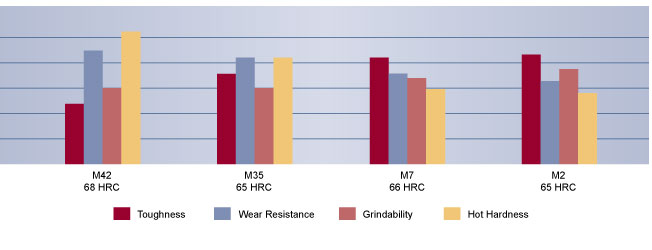

Relative Properties

Physical Properties

- Density: 0.282 lb/in3 (7806 kg/m3)

- Specific Gravity: 7.81

- Modulus of Elasticity: 30 x 106 psi (207 GPa)

- Machinability: 35-40% of a 1% carbon steel

Heat Treating Instructions

Hardening

| Critical Temperature: | |

| Ac1: 1560°F (849°C) | |

Preheating: Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1500-1600°F (816-871°C), and equalize.

Austenitizing (High Heat): Heat rapidly from the preheat.

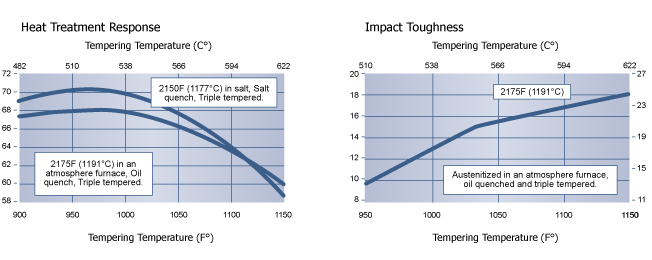

Furnace: 2150-2175°F (1177-1191°C)

Salt: 2125-2150°F (1163-1177°C)

To maximize toughness, use the lowest temperature.

To maximize hot hardness, use the highest temperature.

Quenching: Pressurized gas, warm oil, or salt. For pressurized gas, a rapid quench rate to below 1000°F

(538°C) is critical to obtain the desired properties.

For oil, quench until black, about 900°F (482°C), then cool in still air to 150 -125°F (66-51°C).

For salt maintained at 1000-1100°F (538-593°C), equalize, then cool in still air to 150 -125°F (66-51°C).

Tempering: Temper immediately after quenching. Typical tempering range is 950-1050°F (510-566°C). Hold at temperature for 2 hours, then air cool to ambient temperature. Triple tempering is required.

Annealing

Annealing must be performed after hot working and before re-hardening.

Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1500-1575°F (843-857°C), and hold for 1 hour per inch (25.4 mm) of thickness, minimum of 2 hours. Then cool slowly with the furnace at a rate not exceeding 50°F per hour (28°C per hour) to 1000°F (538°C). Continue cooling to ambient temperature in the furnace or in air. The resultant hardness should be 269 HBW or lower.

Forging

Preheat to 1200-1400°F (649-760°C) and equalize. Then heat rapidly to 2000-2100°F (1093-1149°C) and equalize prior to forging. Reheat if work piece temperature falls below 1800°F (982°C). After forging, cool slowly to ambient temperature in the furnace or buried in insulating material, then anneal as described above.