O1 Tool Steel

O1 Tool Steel is the original oil-hardening, “non-shrinking” tool steel that can be hardened to the Rockwell C 65 range from a low austenitizing temperature. O1 is a general-purpose tool steel that is typically used in applications where alloy steels cannot provide sufficient hardness, strength, and wear resistance.

APPLICATIONS: Where greater dimensional stability in heat treatment or improved wear resistance is required, tool steels with higher alloy contents, such as A2 or D2 should be considered.

Composition

| C | Mn | Si | Cr | W |

| 0.94 | 1.20 | 0.30 | 0.50 | 0.50 |

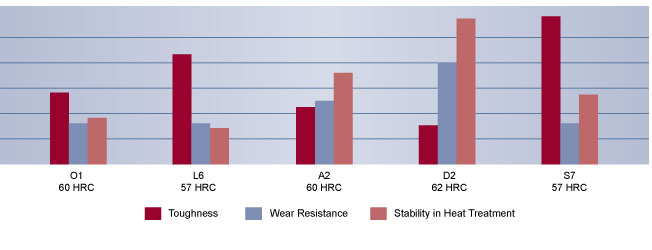

Relative Properties

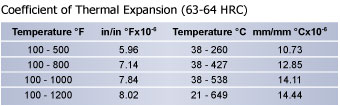

Physical Properties

- Density: 0.283 lb/in3 (7833 kg/m3)

- Specific Gravity: 7.83

- Modulus of Elasticity: 31 x 106 psi (214GPa)

- Machinability: 85-90% of a 1% carbon steel

Heat Treating Instructions

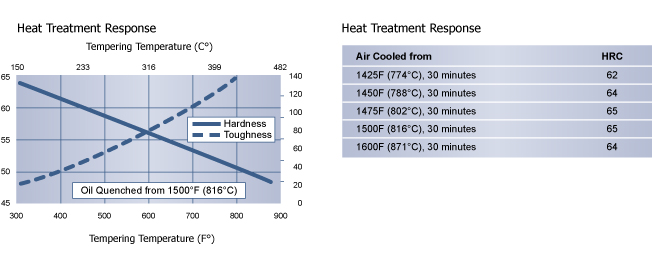

Hardening

| Critical Temperature: | |

| Ac1: 1350°F (732°C) | Ac3: 1400°F (760°C) |

| Ar1: 1295°F (703°C) | Ar3: 1240°F (671°C) |

Preheating: Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1200-1300°F (649-704°C) and equalize.

Austenitizing (High Heat): Heat slowly from the preheat to 1475-1500°F (802-816C)

Soak for 30 minutes for the first inch (25.4 mm) of thickness, plus 15 minutes for each additional inch (25.4 mm).

Quenching: Oil quench to a temperature no lower than 150-125°F (66-51°C).

Note: O1 is somewhat prone to quench cracking, especially if there are significant changes in section thickness and sharp internal corners. The oil quenching should be performed so that the heat removal is as uniform as possible in all areas of the part being quenched. Be sure to remove the part from the oil before the temperature drops to ambient temperature. Hot oil at a temperature of 300 to 400°F (149-204°C) is recommended.

Tempering: Temper immediately after quenching. Do not allow the part to cool below 125°F (51°C). The typical tempering range is 350 - 400°F (177 -204°C). Hold at temperature for 1 hour per inch (25.4 mm) of thickness, 2 hours minimum, then air cool to ambient temperature. To minimize internal stresses in cross sections greater than 3 inches (76.2 mm) and to improve stability in parts that will be EDM’d after heat treatment, a soaking time of 4 to 6 hours at the tempering temperature is strongly recommended.

Cryogenic Treatment: Refrigeration treatments should typically be performed after the temper, and must be followed by a second temper.

Annealing

Annealing must be performed after hot working and before re-hardening.

Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1425 -1450°F (802-816°C), and hold at temperature for 1 hour per inch (25.4mm) of maximum thickness; 2 hours minimum. Then cool slowly with the furnace at a rate not exceeding 50°F per hour (28°C per hour) to 1000°F (538°C). Continue cooling to ambient temperature in the furnace or in air. The resultant hardness should be a maximum of 212 HBW.