CPM Rex 76 Powder Metal High Speed Steel

PM M48 super high speed steel is a high-performance high speed steel which exhibits superior hot (red) hardness compared to T15 and M42 high speed steels, and wear resistance comparable to that of T15. Can be heat treated to 70 HRC, and the high cobalt content enables the steel to maintain high hardness at elevated service temperatures. Vanadium carbides provide the high wear resistance, and the fine grain size, small carbides, and superior cleanliness of the powder metallurgy (PM) microstructure maximize the toughness of the steel. Offers improved cutting tool life compared to the M-series high speed steels.

APPLICATIONS: Form tools, broaches, milling cutters, hobs, and special cutting tools where high hot hardness is required.

Composition

| C | Mn | Si | Cr | W | Mo | V | Co |

| 1.55 | 0.20 | 0.40 | 4.00 | 10.00 | 5.25 | 3.10 | 9.00 |

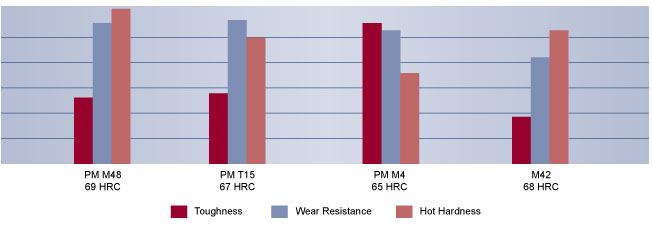

Relative Properties

Physical Properties

- Density: 0.298 lb/in3 (8256 kg/m3)

- Specific Gravity: 8.26

- Modulus of Elasticity: 30 x 106 psi (214 GPa)

- Machinability: 10-15% of a 1% carbon steel

Heat Treating Instructions

Hardening

Critical Temperature: Ac1: 1535°F (835°C)

Preheating: 1500-1550°F (816-845°C), equalize.

A second preheat at 1850-1900°F (1010-1040°C) is recommended for vacuum hardening.

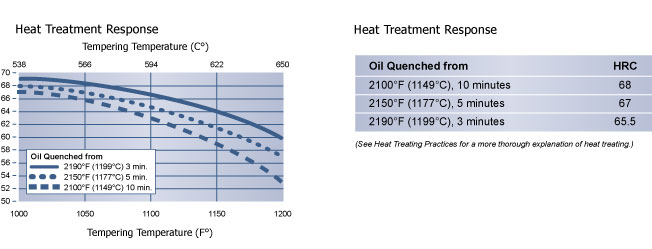

Austenitizing (High Heat): Heat rapidly from the preheat. Soak for 3 to 10 minutes, depending upon the temperature.

Furnace: 2125-2200°F (1163-1204°C)

Salt Bath: 2100-2190°F (1149-1199°C)

Quenching: Pressurized gas, warm oil, or salt.

For pressurized gas, the furnace should have a minimum quench pressure of 4 bars. A quench rate of approximately 400°F (222°C) per minute to below 1000°F (538°C) is critical to obtain the desired properties.

For oil, quench until black, about 900°F (482°C), then cool in still air to 150-125°F (66-51°C).

For salt maintained at 1000-1100°F (538-593°C), equalize in the salt, then cool in still air to 150-125°F (66-51°C).

Tempering: Temper immediately after quenching. Typical temperature range is 1000-1100°F (538- 593°C). Do not temper below 1000°F (538°C). Hold at temperature for 2 hours then air cool to ambient temperature. Triple tempering is required. Quadruple tempering is required when austenitized at 2175°F (1190°C) or higher.

Annealing

Annealing must be performed after hot working and before re-hardening.

Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1575-1600°F (857-871°C), and hold at temperature for 1 hour per inch of maximum thickness; 2 hours minimum. Then cool slowly with the furnace at a rate not exceeding 50°F per hour (28°C per hour) to 1000°F (538°C). Continue cooling to ambient temperature in the furnace or in air. The resultant hardness should be a maximum of 311 HBS.

*CPM, 1V, 3V, 9V, 10V, 15V, S30V, S90V, Rex M4, Rex T15, and Rex 76 are trademarks of Crucible Industries LLC