S7 Shock-Resisting Tool Steel

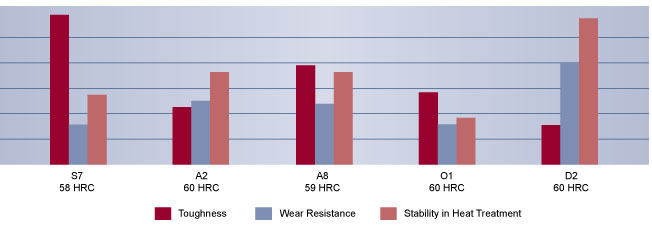

S7 Shock-Resisting Tool Steel is an air or oil hardening tool steel that is characterized by very high impact toughness. The combination of strength and high toughness makes it a candidate for a wide variety of tooling applications. It can be used successfully for both cold and hot work applications. Also suitable for hot work tools where the operating temperature does not exceed 1000°F (538°C). For plastic injection molds, S7 tool steel is available as a remelted, mold-quality product. The remelting process minimizes the number and sizes of nonmetallic inclusions in the steel, and thereby enhances the polishability for critical cavity, insert, and other tooling surfaces.

APPLICATIONS: Recommended for cold work tools that require resistance to high impact and shock loading, such as shear blades, swaging dies, gripper dies, chisels, and punches.

Composition

| C | Mn | Si | Cr | Mo |

| 0.50 | 0.75 | 0.25 | 3.25 | 1.40 |

Physical Properties

- Density: 0.283 lb/in3 (7833 kg/m3)

- Specific Gravity: 7.83

- Modulus of Elasticity: 30 x 106 psi (207GPa)

- Thermal Conductivity: 16.5 BTU/hr-ft-°F (28.5 W/m/°K)

- Machinability: 70-75% of a 1% carbon steel

Heat Treating Instructions

Hardening

| Critical Temperature: | |

| Ac1: 1460°F (793°C) | Ac3: 1540°F (838°C) |

| Ar1: 1390°F (754°C) | Ar3: 1310°F (710°C) |

Preheating: Heat at a rate not exceeding 400°F per hour (222°C per hour). For complex and large tools, heat to 1150-1250°F (621-677°C) and equalize. Then heat to 1300-1400°F (704-760°C) and equalize. For simple geometries, use only the second preheating temperature range.

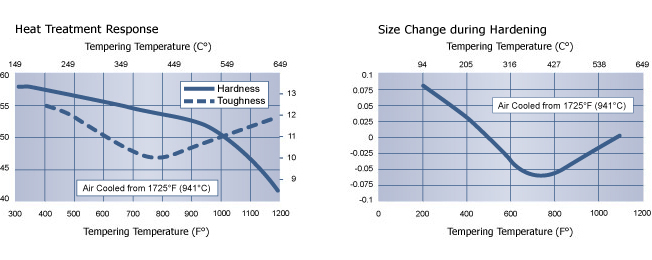

Austenitizing (High Heat): Heat slowly from the preheat. Furnace or Salt: 1725°F (941°C). Soak for 30 minutes for the first inch (25.4 mm) of thickness, plus 15 minutes for each additional inch (25.4 mm) of thickness.

Quenching: Air, pressurized gas, or warm oil to 150-125°F (66-51°C). Note: Sizes over 2½ inches (63.5mm) in cross section will not achieve full hardness by cooling in air. It is necessary to increase the quench cooling rate between 1400 to 900°F (760 to 482°C) by using pressurized gas or an interrupted oil quench. For the oil quench, quench until black, about 900°F (482°C), then cool in still air to 150-125°F (66-51°C).

Tempering: Temper immediately after quenching. Hold at temperature for 1 hour per inch (25.4 mm) of thickness, 2 hours minimum, then air cool to ambient temperature. The typical tempering range for cold work tools is 400 to 500°F (204 to 260°C).

To minimize internal stresses in cross sections greater than 6 inches (152.4 mm) and to improve stability in tools that will be EDM'd after heat treatment, a soaking time of 4 to 6 hours at the tempering temperature is strongly recommended.

For hot work tool applications, tempering at a temperature in excess of 900°F (482°C) is recommended, and double tempering is required.

Cryogenic Treatment: Some prefer to do cryogenic treatment as an extension of the quench from the austenitizing treatment. Others prefer to cryogenically treat after tempering.

Annealing

Annealing must be performed after hot working and before re-hardening.

Heat at a rate not exceeding 400°F per hour (222°C per hour) to 1550°F (843°C), and hold at temperature for 1 hour per inch (25.4mm) of maximum thickness; 2 hours minimum. Then cool slowly with the furnace at a rate not exceeding 50°F per hour (28°C per hour) to 1000°F (538°C). Continue cooling to ambient temperature in the furnace or in air. The resultant hardness should be a maximum of 223 HBW.