W1 Tool Steel

W1 is a water hardening cold work tool steel that is supplied as drill rod in sizes from .062" to 2" round.

APPLICATIONS: Shafts, pins, blacksmithing tools, and a variety of short-term wear tooling. W1 Drill Rod is typically supplied in 36" lengths and can be special ordered as twelve foot bars.

Composition

| C | Mn | Si | Cr | Mo | W | V |

| .95/1.05 | .3/.4 | .1/.25 | .15 | 1 | .15 | .1 |

Heat Treating Instructions

Annealing: Heat to 1375 to 1400° F, soak until uniformly heated, approximately, one-half hour per inch. Furnace cool 50° F per hour to 975° F, air cool to room temperature. Approximate annealed hardness 200 Max. Brinell.

Preheating: Heat to 1200° F, hold at this temperature until thoroughly soaked.

Stress Relief of Unhardened Material: Heat slowly to 1200 to 1250° F. Soak for two hours per inch of thickness at heat. Soak, slow cool (furnace cool if possible) to room temperature.

Hardening

Preheating: Heat to 1200° F, hold at this temperature until thoroughly soaked.

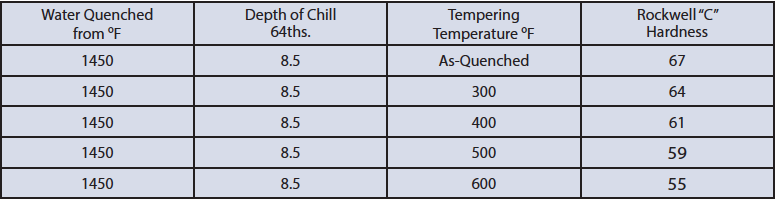

Hardening: Heat to 1425 to 1475° F. Soak at heat for 30 minutes per inch of thickness. Temperatures on the high side of the range will increase the depth of the case.

Quenching: This material may be water quenched, but brine quenching is preferred. Water or brine quench to 150 to 200° F. Oil quenching is sometimes used for light sections and where maximum hardness is not required.

Tempering: Normally water hardening steels need be single tempered only. However, double tempering may sometimes be preferred. Soak at heat for two hours per inch of thickness for each temper. Air cool to room temperature between tempers.

Machinability

W1, in the annealed state, machines at 100% of a 1095 carbon steel.